What is Extrusion Line?

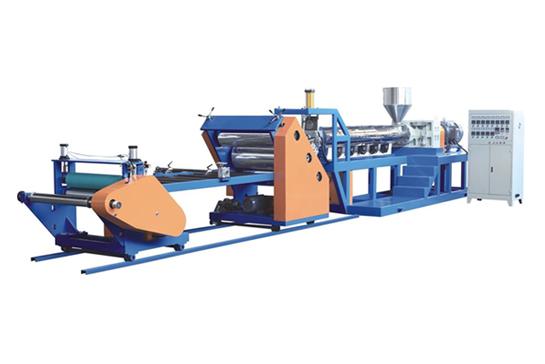

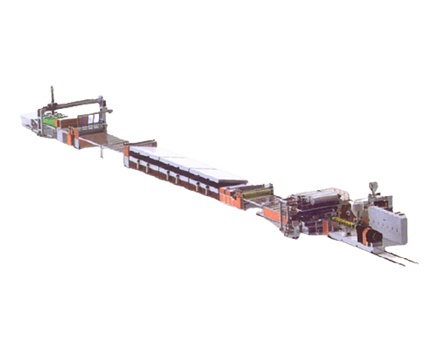

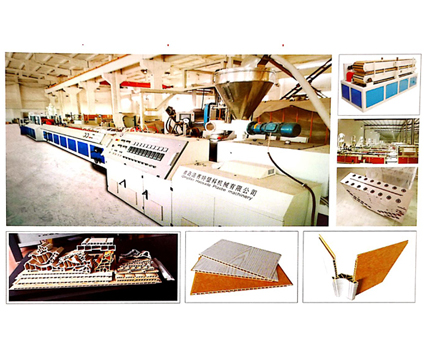

The plastic extrusion line is a mass production process in which the raw material plastic is melted and formed into a continuous contour. Extruded items include pipes, weather strips, window frames, plastic sheeting, tape and wire insulation. Our company is a very good extruder line manufacturer, we have many extrusion line factories. We are proud to have a complete plastic sheet extrusion production line, plastic pipe extrusion production line, plastic profile extrusion production line and wood plastic extrusion line. Our engineers and technicians use their expertise and development techniques to adapt to the latest plastic extruders in the rapidly changing market.

Processing of Plastic Extrusion Line

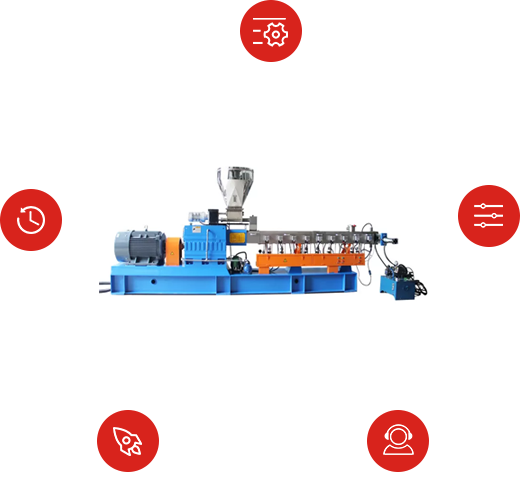

At the beginning, small plastic particles are put into the hopper placed on top of the barrel. The barrel is a heating hollow cylinder, a bit like a very thick tube. The screw type screw rotates inside the barrel. The rotation of the screw brings and pushes the plastic particles into the barrel. When the pill moves to the front end of the cylinder, the friction and electric heat of the cylinder will melt the plastic.

After the plastic melts, the rotating screw continues to act as a pump and forces the molten plastic through the mold. The mold is usually a piece of steel with the desired part shape. Once the melted plastic leaves the mold, it will be shaped like a finished product. Next, pull it through some kind of cooling device, usually using air or water for cooling. After cooling, the product can be rolled up, cut into sections, packaged or subjected to secondary operations.

How do Plastic Extruders Work

The principle of plastic extrusion line: Plastic pellets(eg.PE PP,PVC, PA, EVA) firstly come through hopper. Under the power system, heating, melting the pellets,pressing, screw' s rotation, then generate shear heat, pass the barrel channel, reach screen pack, the products are extruded. This is done by extrusion line machine. The shape is variable according to different mould. This will be finished during plastic production line. We can also mix color depending on different requirement. General includes standard pipe, sheet,board, profile and different shape's ones.

EN

EN

fr

fr  es

es  it

it  ru

ru  ar

ar  da

da  fi

fi  pl

pl  bg

bg  nl

nl

Call us on:

Call us on:  Email Us:

Email Us:  No.398B-9, Jiaozhou West Road, JiaozhouCity, Qingdao City, China.

No.398B-9, Jiaozhou West Road, JiaozhouCity, Qingdao City, China.